Croze Nest Cooperage

Hand Crafted Whiskey Bourbon Barrels

As a whiskey lover…why is barrel making important to know?

Today’s episode, I visited a cooperage in Grand Rapids to learn how a whiskey bourbon barrel creates all the beautiful, delicious layers of flavor and color in our favorite whiskeys and bourbons.

Now remember a bourbon must be at least 51% corn in the mash bill (recipe), not have any additives like (caramel flavorings) and aged in new charred white oak barrel.

The Master Distiller creates a mash bill to achieve the best whiskey bourbon from each season’s crop of corn, wheat and rye. It’s part science, part wisdom, part intuition.

So, now the question becomes… is it the mash bill with the corn sweetness… or the new charred white oak barrel that ages the bourbon that gives it the perfect blend of vanilla, caramel, or nuttiness flavoring?

Distillers and Coopers will never agree!

However, when a distiller wins awards on their whiskey or bourbon…you can bet others are going to find out who makes that barrel!

And that is why in less than 5 years the Croze Nest has become so popular.

Distillers throughout in Michigan (and four other states), are seeking Croze Nest owner and cooper, Joe Smith to get his prime, handcrafted white oak barrel with just the right amount of charred layer, to give them the final ingredient to age their recipe in.

Joe uses white oak from Missouri where it is cut, naturally aged and then cut to order throughout the US. Upon receiving his shipment, Joe ages the wood yet again before he cuts his order.

Think about this process a minute. You have a tree that was grown in Missouri, cut and aged naturally there for x amount of time, and depending on the season, (temperature, rain, snow, etc.), plus bugs, fungus in that area – all of it is absorb into the wood.

Now staves (narrow pieces of wood boards) are shipped to the Croze Nest in northern lower Michigan and it’s aged again to retain Michigan’s weather, bugs, fungus and whatnot.

The science behind this process can be mind boggling, especially once the barrel is made – by either hand or machine, and then it’s filled and stacked in a rack house at the distiller’s location where the environment and temperature are factored in again for the aging process.

During the aging process, the Angel Share takes it’s portion, which allows room in the barrel for air, – then the whiskey/bourbon starts to really absorb the charred oak wood and the chemical reaction is nothing but pure magic. The sweetness and layers of flavor come through and it’s now a waiting game until it is properly aged.

At Croze Nest, Joe constructs his barrels by hand. Depending on size, each stave, is cut to precision to have the correct angle to fit the edges of the barrel together tightly and without adhesives, nails or screws.

He then places the staves in a holder with one ring at the bottom until it forms the barrel. He hammers on two of the rings and uses a fastener to hold the other end in place.

The barrel is now ready for the fire, Joe places the barrel over a small fire to heat the barrel so it can be bent into shape. The barrel is not charred at this point, it is warmed, sprayed with water, and warmed again until dry. It takes about 15 minutes for this step, and he checks it frequently with his hand to know exactly when he thinks it’s ready. Once the barrel is heated to the right temperature, Joe has 5 minutes to get it to bend into the shape of the barrel.

The barrel shaper, which he designed, applies over 600 pounds of pressure to push the staves together airtight. He can now add the last two rings to secure it.

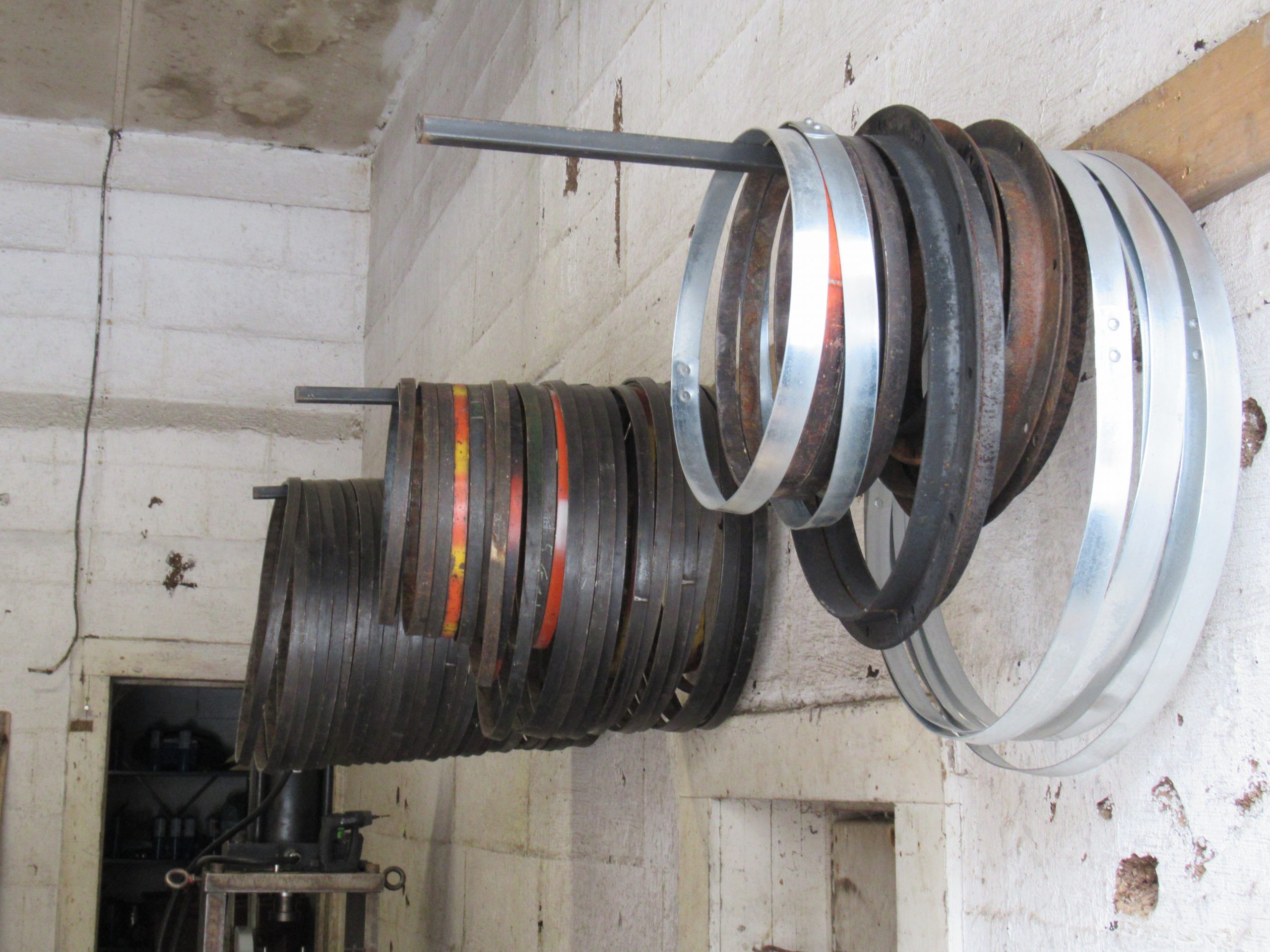

Joe makes his own rings for the barrels too! He orders in stainless steel and cuts and bends them into the sizes he needs. He then uses the Croze Nest initials to brand the barrel as his. He can quite often spot his barrels over others, because the bands have not rusted, and the seal is still held over the years with his initials still in tack.

Meanwhile the barrel is ready to be charred. Joe uses the sawdust from his shop to create a fire inside the barrel. It only takes a few minutes, and a hot fire to char the barrel, and Joe knows that exact amount needed for each of his customers.

The amount of char will determine how much color and flavor it will add to the bourbon.

The lid, or head, to each end of the barrel is cut precisely, and is also charred to fit each barrel so that there is no leakage. (Except for the Angels share!)

It was snowing and a chilly 32 degrees, and we spent most of the afternoon talking and going over how the barrow is made. Joe graciously demonstrated each step, the equipment he designed to create his barrels and the barn he houses his business in. His passion for his craft is certainly seen and felt as he talks about his business and family.

During our conversation, Joe told me that he had learned about a grandfather from 10 generation ago that also was a cooper on the Mayflower. As it turns out that grandfather was quite know and you can find his story in many places online. Wikipedia is just one source I found that had the story about Joe’s grandfather John Alden, you can read more about him here.

Craft barrel making by hand has been a lost art. The cost of the machines to make barrels commercially are well into the millions, but Joe was determined to find a way. Much of the machinery that was needed to cut or bend the wood in Joe’s shop he either designed and built, or re-purposed other types of equipment to fit his needs. His determination has paid off!

Listen in and hear the rest of his story on my podcast.

Recent Comments